Handmade and made to last

At Crow Leather, we personally handcraft every belt and wallet, assuring quality products.

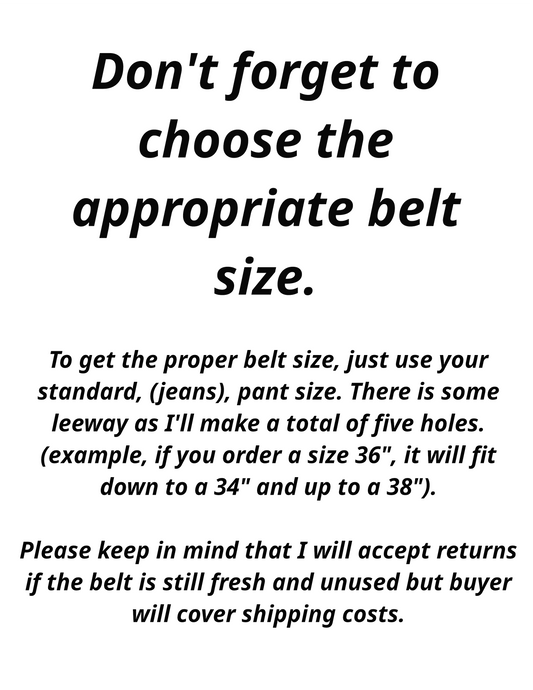

We make durable and solid belts that stand up to rough work, yet stylish and elegant enough for the office or a wedding. They are so versatile you'll want to get a couple. Made from quality, single layer, vegetable tanned cowhide, with the exception of our no-nonsense buffalo hide straps, these belts are as natural as you can get 'em and will last for years to come. We specialize in belts, but when we get a minute, we love to make up some outstanding wallets as well. Whether you're looking for a simple card wallet, classic bifold or a bit more of an organizer, we've got something for you. Whichever product you chose, rest assured that it's well made with quality materials and that a proper inspection is always done before passing it on to you.

Leather Belts

-

Top Sellers

These are my Top Four best selling belts. All four are a...

-

Embossed Leather Belts

These belts are made from 8/9oz vegetable tanned cowhide geared toward great...

-

Tooled Leather Belts

These simple tooled belts carry more charm and elegance than any of...

Wallets

-

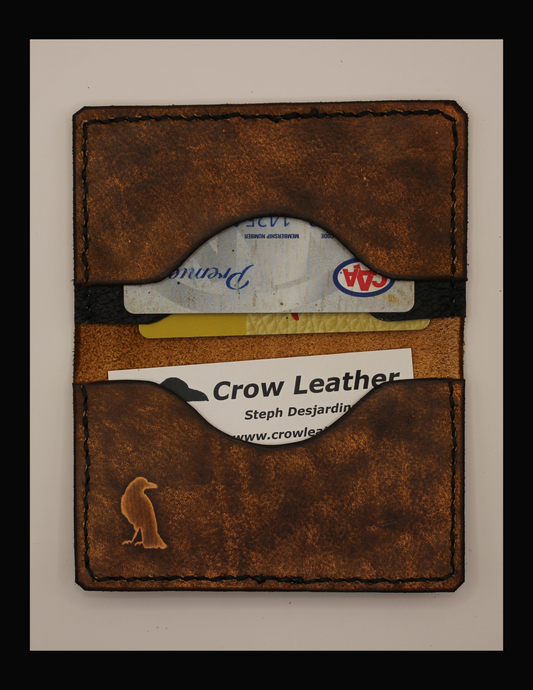

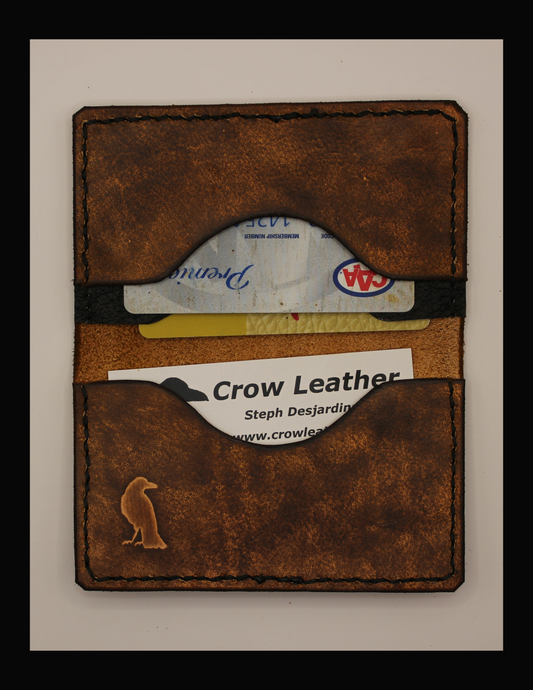

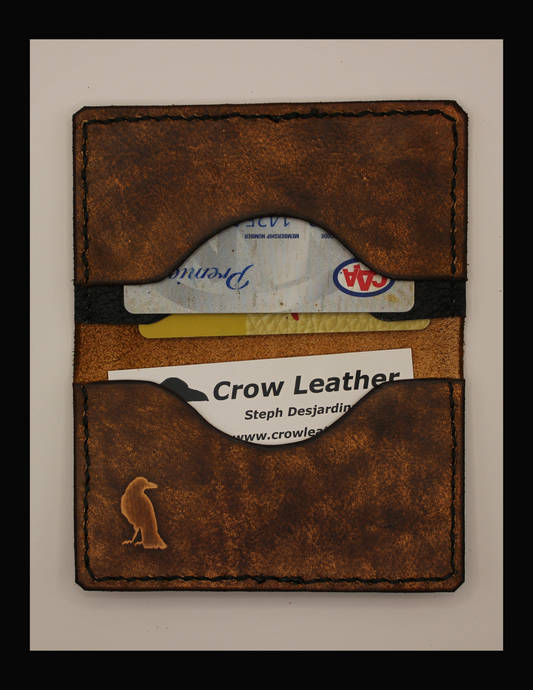

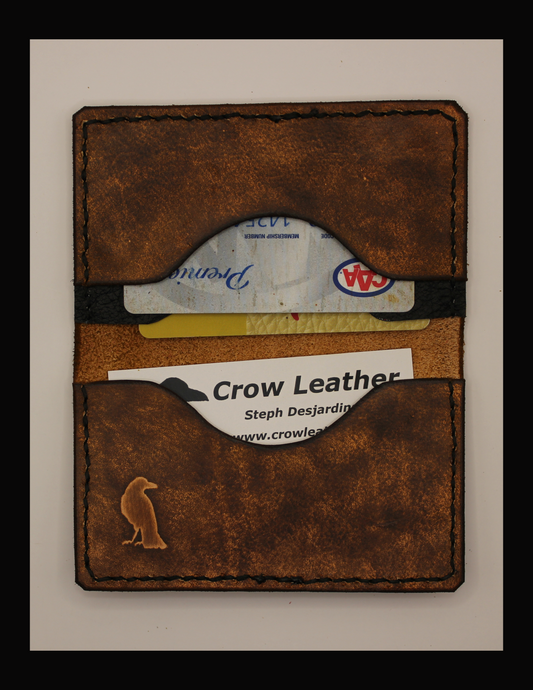

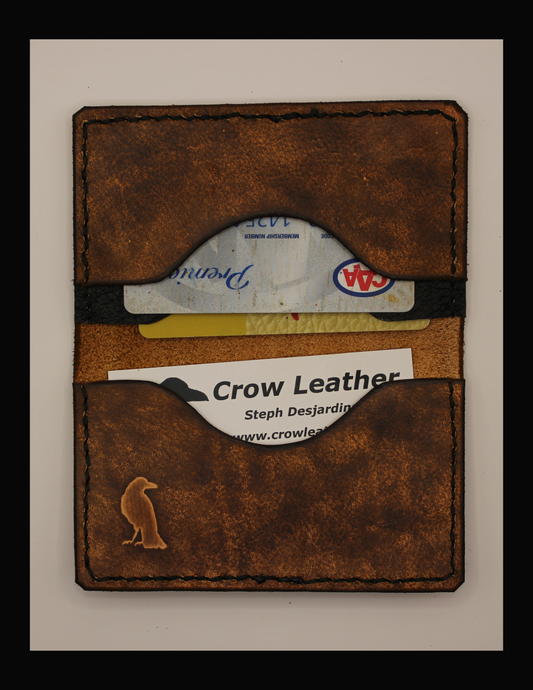

No. 7 Folding Card Wallet

The No. 7 Folding Card Wallet is a minimalist wallet aimed to...

-

No. 10 Bifold Wallet

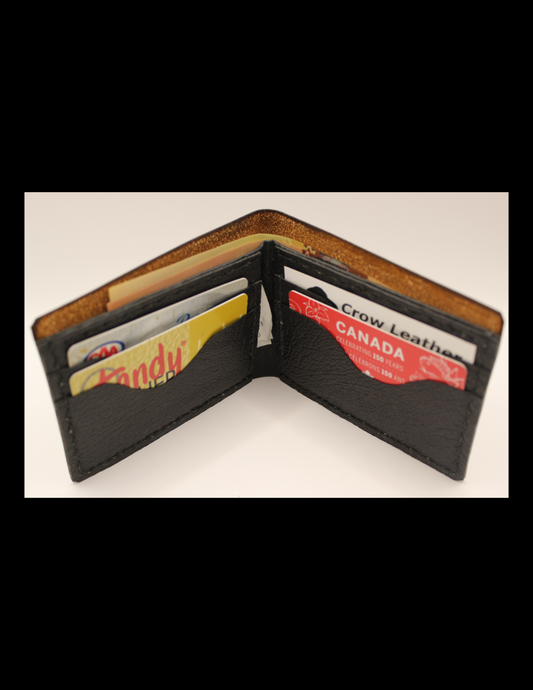

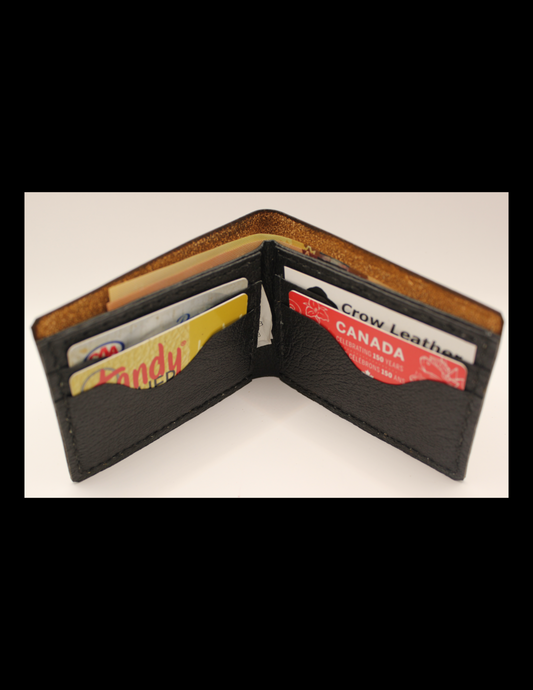

This classic style has been a great seller for men, and ladies,...

-

N0. 13 Long Wallets

The No. 13 wallet is the ultimate in organizing cards, cash, bills,...

Full gallery of products

-

Black Buffalo Hide Belt

Regular price $50.00 CADRegular priceUnit price / per -

Brown Buffalo Hide Belt

Regular price $50.00 CADRegular priceUnit price / per -

Leather belt, 12 Gauge

Regular price $60.00 CADRegular priceUnit price / per -

Leather Belt, Circular Saw Blade

Regular price $70.00 CADRegular priceUnit price / per -

Leather Belt, Classic Plain

Regular price $60.00 CADRegular priceUnit price / per -

Leather Belt, Dragon and Celtic Knot

Regular price $60.00 CADRegular priceUnit price / per -

Leather belt, Sportsman

Regular price $60.00 CADRegular priceUnit price / per -

N0. 7 Folding Card Wallet, Classic Brown

Regular price $40.00 CADRegular priceUnit price / per -

No. 10 Bifold Wallet, Bolts & Cogs

Regular price $70.00 CADRegular priceUnit price / per -

No. 10 Bifold Wallet, Classic Plain

Regular price $65.00 CADRegular priceUnit price / per -

No. 10 Bifold, Black

Regular price $65.00 CADRegular priceUnit price / per -

No. 13 Long Wallet, Bolts & Cogs

Regular price $100.00 CADRegular priceUnit price / per -

No. 13 Long wallet, Cherry

Regular price $90.00 CADRegular priceUnit price / per -

No. 13 Long Wallet, Classic

Regular price $90.00 CADRegular priceUnit price / per -

No. 7 Folding Card Wallet, 12 Gauge

Regular price $45.00 CADRegular priceUnit price / per -

No. 7 Folding Card Wallet, Badass

Regular price $60.00 CADRegular priceUnit price / per -

No. 7 Folding Card Wallet, Bat Shit Crazy

Regular price $60.00 CADRegular priceUnit price / per -

No. 7 Folding Card Wallet, Cherry Owl

Regular price $45.00 CADRegular priceUnit price / per -

No. 7 Folding Card Wallet, Flower

Regular price $45.00 CADRegular priceUnit price / per -

No. 7 Folding Card Wallet, Four Twenty

Regular price $60.00 CADRegular priceUnit price / per -

No. 7 Folding Card Wallet, Fuck Sakes

Regular price $60.00 CADRegular priceUnit price / per -

No. 7 Folding Card Wallet, horse

Regular price $45.00 CADRegular priceUnit price / per -

No. 7 Folding Card Wallet, Outdoor

Regular price $50.00 CADRegular priceUnit price / per -

No. 7 Folding Card Wallet, Owl

Regular price $45.00 CADRegular priceUnit price / per -

Pinstripe Leather Belt

Regular price $65.00 CADRegular priceUnit price / per

More about Crow Leather

About the maker

Steph Desjardins, creator/designer ofCrow Leather.

After watching my father craft leather intermittently since my childhood, I gave it a go myself in the winter of ‘13 and have been craftin’ and stitchin’ since. With a carpentry back ground, and an open mind, I embraced this new trade, new skills, and I still love challenging myself with new projects. We live on a small homestead in a forest lot on Manitoulin Island with three kids, so the option to work from home has been a blessing for us. Being a father, husband, homemaker, builder, goat herder, chicken chaser and sometimes gardener, I’m thankful I do something I love ‘cause it might be hard at times to find motivation at 10:38 at night to return to my shop. I love the Zen of punching out 795 holes for a satchel, the evolution of staining a piece of leather, stitching a wallet while watching/listening to Jeopardy.

About the process

When purchasing my raw materials I look for quality in the consistency of thickness, how well it cuts and emboss or tools and also how the leather takes in stains and dies. Every project or item requires consideration in regards to many factors, thickness and type being the firsts. They will make up the bones of the project, embossing and staining are the detailing, the art. At this point, I still hand stitch all my items. I have, in a strange way, found a cool comfort in stitching. It mostly all happens at the end of a project, so there’s that satisfaction of wrapping up, but it’s more than that for me. It’s like sitting in a rocking chair, like having Jeopardy or Firefly in the background, like rocking a baby to sleep... when they actually ... go ... to ... sleep. Or driving down a straight stretch of highway with no other vehicle in sight. It sure keeps my hands busy, though, if not completely out of trouble.Of all the ways I’ve made a living, leather smithing has been a very cool and interesting ride. I see it as a practical skill which allows for loads of creativity and I can see myself continuing in this area for years to come.

Choosing the right leather

If I’m making a belt, I will use 7/8oz to 9/10 veg tan leather that I strap. Wallet covers are made from 2/3oz cowhide. For most satchels I will mainly use a 3/4oz veg tan leather. Finally, I will take a durable yet still flexible 5/6oz for knife and ax sheaths as well as guitar straps. Other than my wallet inners I mostly use veg tan leather as opposed to chrome leather. Veg tan leather is your ideal material to tool and carve as well as mold or form. It’s the old school bark tanning method. Hence vegetable tan. This method takes from 30 to 45 days. Chrome tan is a more modern Approach to tanning and uses a more modern/chemical to tan things and only takes 24 to 48 hours to process. The end product is quite different. Chrome leather won’t emboss or take dies or stains, Including revitalizing waxes and oils, and so won’t last as long with use.

Some of the tools I use

Every projects starts with a design or pattern. To trace, I use a straight up pen, for most projects, a white grease pen for dark materials and sometimes a scratch awl. Cutting involves a few tools. The main being a small handled utility knife, a pen x-acto knife and a skiving knife. I have an old school plastic handled Singer scissor that just kicks a&& as well for a few lighter projects. When embossing, I damp down the leather with a wet sponge, veg tan of course, if your following, and either hammer/stamp or free hand an impression in the project. In tooling, there’s the art of carving, which can create some epic details in leather and these are mainly done on veg tan as well. It’s not a skill I’ve acquired but I’m fascinated with. When staining, I use an alcohol base die with basically two methods of delivery. The standard sponge brush works well for me to stain the back of my belts or key fobs or when making a “straight/plain” belt. For my visible or “canvas” side I use a nice cotton or linen rag which, using previously mentioned sponge brushes, gets damped up and then I gently circle brush on my project. This method is what, I feel makes my creations come to life because it creates a contrast, a different shade, as the dye doesn’t stain the depressions fully. I use a 1mm nylon thread, dark brown or black mainly, and a medium Glover’s needle. Sharp little buggers they are. I make stitching holes using a set of leather chisels, which resembles small forks, and use a small and very pointy awl to completely prepare for stitching. Slightly different approach to every project. I’ll use use lacing and a darning needle for satchels and such projects as well

Notes on hardware

Hardware is also very important, you don’t want to build a nice product and then have the shiny bits fall off in a few months. On that same note, I do my best to find sweet hardware at an affordable cost so long as it stands up. Buckles, snaps, rivets and satchel closures can be decorative but they need to withstand the every day forces and abuse we bring them.Once all done, I sell the items at crafters markets, preferably juried, or online through FB or Instagram as well as my website. I also wholesale to a few stores, which is always nice.